Inline Homogenizer, Inline Emulsifying Mixer, Inline High Shear homogenizer

Inline Homogenizer , Inline Emulsifying Mixer

This enables any machine to combine, emulsify, homogenize, solubilize, suspend, disperse and disintegrate solids.

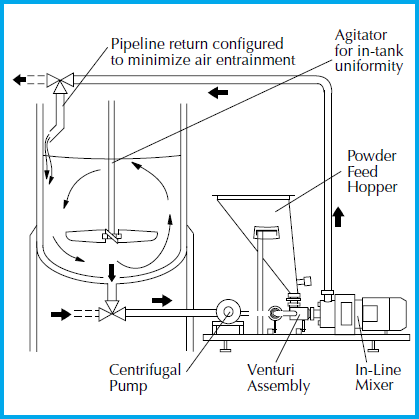

Inline Homogenizer machine is self-pumping quality specified providing a centrifugal pumping action with no want of external pumps. The stators are simply modified as per particle needed sizes for the blending method inline.

| Inline Homogenizer, Inline Emulsifying Mixer

|

Inline High Shear homogenizer is to be designed for inline high shear mixers. that is ineffective in combination. It performs a unique style of operation combination

- Rotor And stator kind.

- self-propelled vehicle Mounted, With atomic number 94 Wheels and Support for simple Handling.

- Completely different style of a mechanical device (coarse/medium/fine) for Specific Particle Size Reduction.

inline homogenizer with Tank , control systems

Depending on the rotor/stator pure mathematics, an inline mixer will handle viscosities up to ten,000-20,000 cP while no external pumping help. With a donkey pump, it will method products up to two hundred,000 cP.

line Homogenizer

Inline Homogenizer Mixer Structure

Emulsifying Homogenizer Pump Three Stage

Emulsifying Homogenizer Pump Three stage Parts

Inline Homogenizer Emulsification Pump Feature:

● Continuous large production capacity, materials 100% through the dispersing and shearing.

● Hygienic stainless steel design

● 3A sanitary standards, IEC B35 motors, IP55, F-class insulation, 50HZ/60HZ.

● Easily maintenance, no need special tools and staff.

● No damage when starting the test, even if there is a brief reverse rotation

● Compatible with single and double mechanical seal, easy to change.

We manufacture and export a large variety of Inline Homogenizer, that is given exactness designed rotor/stator work head. Our vary will operate higher than typical mixers and facilitate emulsifying, homogenizing, solubilizing, suspending, dispersing, and disintegrating solids.

Rotor/Stator Homogenizer (Inline Mixer)

Rotor/Stator Homogenizer (Inline Mixer)

In method engineering, homogenizers are accustomed to homogeneously combining, smoothing, and milling liquid products, mixtures, and suspensions.

This gives you a finer, sander product with a high reproducible time and short method times. The high shear forces of the rotor-stator tool guarantee optimum product disintegration and break-up particles within the metric linear unit vary.

Food products get an improved sensory (“mouth feel”) and better stability.

In the process of soluble crystals, the wet edge of the crystals achieves a shorter dilution time and therefore shorter production times.

Inline Emulsifying Mixer ,Inline High Shear homogenizer

HOMOGENIZER MIXER MANUFACTURER – EMULSIFYING HOMOGENIZER PUMP TWO / THREE- & FOUR STAGE – HIGH SHEAR MIXER HOMOGENIZER

Single / Two / three and four stage inline dispersing emulsification equipment. The materials are dispersed, sheared, refined, crushed, emulsified, mixed and homogenized by 6-10 layers of rotor and stator. Hygienic design, the surface of parts are finely polished, the mechanical seal complied with FDA standard. It is commonly used in dairy, food processing, beverage, pharmaceutical, cosmetic and fine-chemicals industries…

| Flow rate | 5 to 40 m³/h |

| Body Material | AISI 316L (1.4404)Q |

| Mechanical Seal | single mechanical seal double mechanical seal (recommend on optional extra cost), |

| Max Power | 45KW wide voltage 2P |

| Motor Brand | ABB motor, Siemens , Hindustan , UK Make motor ,standard B35, IEC |

| Temperature | -20 to 140°C |

| Inlet & Outlet Sizes | 1 1/2″-3″ (DN40-DN80) |

| Surface treatment | Ra16-32µin (0.4-0.8µm), Ra 32µin (0.8µm) as default. |

| Certification | US 3-A 02-11, FDA21 CFR 177.2600 comply model |

| Connection type | Tri-Clamp End, Butt Weld End, Thread, Flange |

Homogenizers will be equipped with up to a few rotor/stator sets. The slot widths of the tools will be bespoken to your product and particle size.

- The whole method of dispersing, high cutting off, emulsifying and homogenizing.

- Appropriate for creating ointment, cream, shampoo, lotion, syrup, and alternative emulsions of 2000 to one hundred thousand rate consistency

- Flow by water from zero.5m3/h to 100m3/h

- Appropriate for continuous combination method pipes to the blending for even homogenization

- Cooling system for the mechanical seal for long high shear combination time.

- All contact components are created out of SS 316L/SS 316 and SS 304.

- The specification of the inline continuous mixer complies with cGMP rules.

- Tri-clover connections square measure provided for simple operational and maintenance functions.

- Capability 1HP To 50HP

The homogenizer is usually necessary to combine one or a lot of substances inside a liquid. This device permits micronizing and scatters the particles suspended within the fluid, so that the merchandise becomes extremely stable, notwithstanding the following treatments and stockings the product could bear. The homogenizer delivers unequaled consistency and management of high shear method applications like unmixable section Emulsifying, Homogenizing, Wet Grinding, Texturing, Deagglomeration, and Fine Dispersing.

Inline High Shear Mixer For Your Process

The product arrives at the homogenizing at an occasional speed and air mass (caused by the small gap between the passing head and collision head). throughout the passage, the merchandise is subjected to various forces that cause the particle’s micronization: a violent acceleration followed by an on-the-spot speed that produces cavitations so the globules explosion. sturdy turbulence united to high-frequency vibrations. Collision cutting strengths are derived from the laminal passage between the homogenizing valve surfaces and therefore the following impact with the collision ring.

General Applications of Single / Two / three and four stage Single / Two / three and four stage Inline Homogenizer, Inline Emulsifying Mixer, Inline High Shear homogenizer for Pharmaceuticals: ointment, dental composite, syrup, injection, Cosmetics & Toiletries: cream, lotion, wax, mascara, gel, toothpaste, Chemicals, polyester, synthetic fiber, shoe cream, Food: mayonnaise, dressing, jam, butter, margarine, wasabi.

Inline Homogenizer: Technical Specifications

| Model | Motor power (kw) | Speed (rpm) | Flow rate by water (m³/h) | Inlet/Outlet (DN) |

|---|---|---|---|---|

| AP1.5 | 1.5 | 3000 | 1.5 | 32/32 |

| AP-2.2 | 2.2 | 3000 | 3 | 40/32 |

| AP-3 | 3 | 3000 | 4 | 40/40 |

| AP-4 | 4 | 3000 | 5 | 40/40 |

| AP-5.5 | 5.5 | 3000 | 7 | 50/50 |

| AP-7.5 | 7.5 | 3000 | 8 | 50/50 |

| AP-11 | 11 | 3000 | 12 | 65/50 |

| AP-15 | 15 | 3000 | 16 | 65/50 |

| AP-18.5 | 18.5 | 3000 | 20 | 65/65 |

| AP-22 | 22 | 3000 | 25 | 65/65 |

| AP-30 | 30 | 3000 | 35 | 80/65 |

| AP-37 | 37 | 3000 | 40 | 80/65 |

| AP-45 | 45 | 1500 | 50 | 80/80 |

| AP-55 | 55 | 1500 | 75 | 100/80 |

| AP-75 | 75 | 1000 | 90 | 100/80 |

- Complete process of dispersing, high shearing, emulsifying and homogenizing Single / Two / three and four stage Inline Homogenizer, Inline Emulsifying Mixer, Inline High Shear homogenizer.