- "Best place for one stop solution"

- 91-9898070475

- info@applepackprocess.com

Powder transfer system – PTS Bulk material handling for Dry Powder and Granules

Planetary mixers ,Paste Mixer, Double Planetary Mixers

October 21, 2022

Liquid Detergent Manufacturing Plant: Operation, Project Setting Up with Comprehensive Guide

May 30, 2023Powder transfer system – PTS Bulk material handling in Pharmaceutical, Food / Pet Food, Confectionary, Dairy, Non-Woven, Bakery / Snack Food, Mining / Minerals, Chemical / Petrochemical, Cement, Plastics, Frac Sand / Aggregate, Water Treatment, Gypsum, Recycling, Pulp / Paper, Ethanol / Biofuel, Ceramics, Detergent etc.

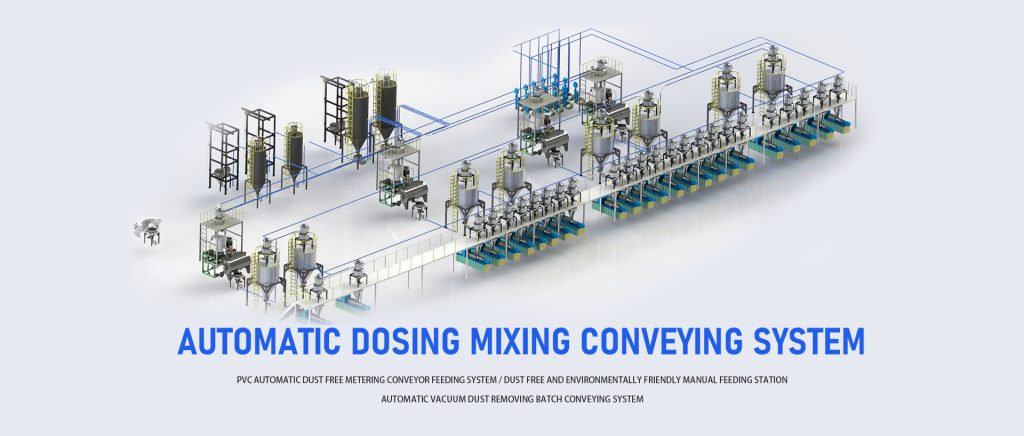

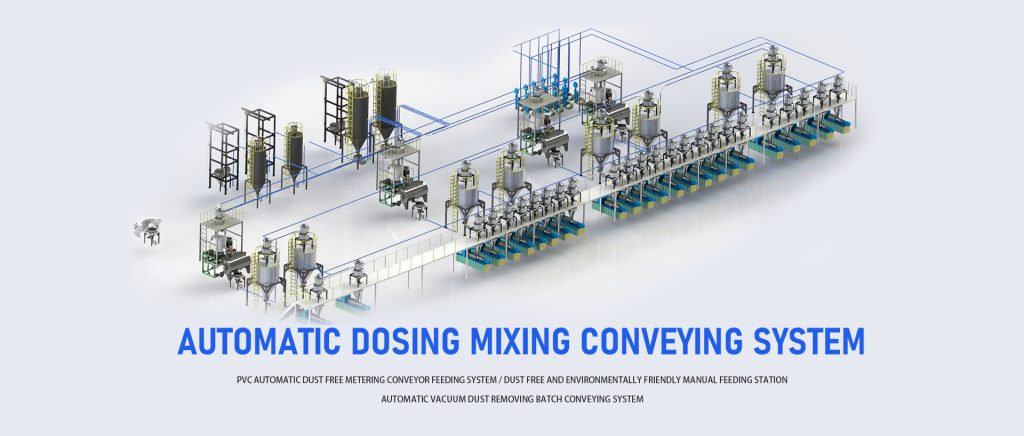

We provide a turnkey solution for energy-saving and environmentally friendly materials′ conveying, automatic weighing and batching, mixing, storage and computer control systems. The main products are: Large raw material storage silos, feeding station, tubular chain conveyor, pneumatic conveying system, screw conveying system, automatic weighing system, mixing unit, industry dust collectors.

pneumatic powder transfer system

Material conveying is the key to realize automation of blending and mixing production line. The conveying system occupies a large proportion in the PVC automatic mixing and mixing system: Transfer of raw materials from the bag opening station to the over silo above the batching scale; Transfer of finished material from mixer to finished material silo; Transfer of finished material from finished product silo to extruder.

powder transfer system

There are two main forms of more used here: spiral conveying and pneumatic conveying. And pneumatic conveying can be selected according to the actual field, such as thin phase positive pressure, thin phase negative pressure, dense phase positive pressure and other ways.

Screw conveyor is composed of motor, reducer, screw body. Simple structure and reliable operation. However, the cost is higher when the transportation distance is longer.

The core part of dense phase pneumatic conveying system: low noise, long conveying distance, low energy consumption, large conveying capacity, low pipe wear and so on. It will not form blockage in the pipeline and there will be no material segregation and stratification. It is especially suitable for conveying mixtures and the use of boosting devices. It can also effectively reduce the material forward speed.

Dilute phase positive pressure pneumatic conveying system: no special compressed air source is needed and the investment is small. But the noise is high, the conveying distance is short, in the conveying process is easy to form the material segregation and stratification.

Dilute phase pneumatic negative pressure conveying system: The advantages and disadvantages are similar to those of lean-phase positive pressure conveying

pneumatic powder transfer system

Feeding systems Application

- Direct Charge Blender Loading powder transfer system

- Conveying Difficult Materials in Food Processing powder transfer system

- Sanitary Hopper and Feeder Refill for Food & Pharmaceutical Processing powder transfer system

- Dry Chemical Vacuum Conveying for Chemical, Petrochemical and Wastewater Processing powder transfer system

- Automatic Batch Counting & Weighing powder transfer system

- Batch Weight Accuracy Guarantees powder transfer system

- Mobile Vacuum Conveying Systems for Powders & Granules powder transfer system

- Vacuum Conveying Systems for Tablet Press Loading powder transfer system

- Pneumatic Conveying Solutions for the Packaging Industry

1. Material collection system

The material collection system is used to collect bulk or bagged raw materials into storage silos in various ways.

Bulk materials can be sent directly to the storage tank through the pneumatic conveying device on the tanker, and the bag materials is collected by the bag opening station.

2. Material conveying system

The conveying of the materials is the key to the automation of the compounding and feeding system. In the PVC automatic compounding system, the conveying system occupies a large proportion: Including the conveying from the bagging station to the transition silo upon the batching scales, the finished materials conveying from the mixer to the finished silo, and also the finished materials conveying from the finished silo to the extruder.

3. Weighing batching system

In the PVC automatic compounding system, the weighing batching system is normally composed of two separate subsystems: a set of main materials weighing batching system and a set of auxiliary materials weighing batching system. Each batching system has the feeding silo for each material, also with the screw conveyor, batching sales and etc.

4. Mixer Unit

The high speed hot and cooling mixer is a preferred equipment suitable for the PVC blending process, which is a combination of a high-speed hot mixer and a horizontal cooling mixer. The high-speed hot mixer has three mixing blades and diversion section etc. Under its action, materials will rotate, flip and other complex movement with high speed, so that the temperature will rise rapidly to meet the requirements of the material mixing process. Then materials enter the horizontal cooling mixer, it will cool down quickly to meet the production process requirement by low-speed mixing blade movement and heat exchange with the water-cooling system.

5. Material storage equipment

Material storage equipment are separately silos mainly used for storing raw materials and finished materials.

Consist with silos, dust removal equipment upon the silos, steel ladder, fences, decompression cap, gate other components etc.

Pneumatic conveying flow rate refers to the rate at which air or materials in pneumatic conveying pipelines travel. The airflow rate directly correlates with air velocity, air volume, and air mass flow, and can impact the solids loading ratio, the chances of pressure loss, the quality of the product being conveyed, and the integrity of internal components.