- "Best place for one stop solution"

- 91-9898070475

- info@applepackprocess.com

Powder Transfer Systems – PTS Sterile process, Sterile/Aseptic Mixing, Blending

Vacuum Homogenizer Mixer, Vacuum Emulsion Mixer – USA, UK, Thailand, Europe

October 28, 2023

Venturi Pneumatic Conveying System for Powder Filling, Transfer systems

November 24, 2023Powder Transfer Systems – PTS Sterile process

Powder Transfer Systems – PTS Sterile process is usually integrated in a process line in a closed way by flexible lines and doesn’t require any disconnection during the operation. The system will be cleaned and sterilized in line with the upstream and downstream equipment.

PTS Sterile process is designed according to the latest cGMP requirements without internal parts or inaccessible areas allowing the system to be sanitized or sterilized with either 90°C hot water or steam.

The system is equipped with various temperature probes for temperature mapping as well as a steam trap valve at the lowest part of the mixer. The vessel is insulated to prevent a direct contact with the vessel wall and keeping heat loss as low as possible.

Vacuum Powder Transfer System

Suitable for facilitating maximum transfer of the powder materials. This is exactly what you stand to gain from our vacuum powder transfer system. Built of high-quality materials hence can last for long. The ergonomic design enhances the usability of the equipment.

Vacuum powder transfer system

Sterile/Aseptic Process overview

Product Sheet

PTS – Powder Transfer Systems – Production Scale- New mixing technology without rotating or moving parts.

R&D Applications -Research & Development – Pilot plants

Options: CIP – SIP – Weighing – High shear propeller – Sampling – Small addition – PAT

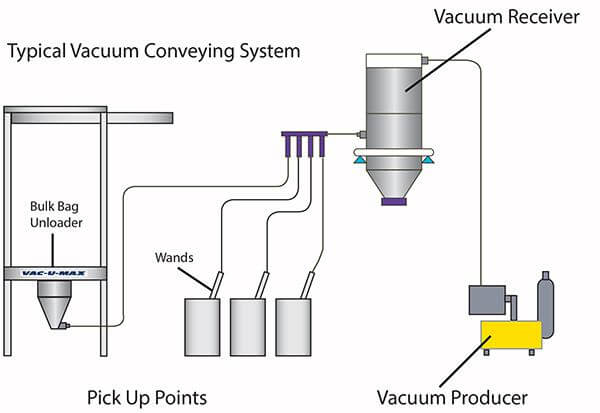

Powder transfer system | Pneumatic Conveying Systems -Powder Transfer System conveys powders and granular products vertically or horizontally to and from process machines

Transferring – PTS – Powder Transfer Systems

Bulk Materials Handling – PTS – Powder Transfer Systems

Dosing / Dispensing – PTS – Powder Transfer Systems

Sampling – PTS – Powder Transfer Systems

Containment Systems with PTS – Powder Transfer Systems

Integrated Applications with PTS – Powder Transfer Systems

The company is known for innovative manufacturer for processing system for drying, granulating, mixing, milling, size reducing, blending, tabletting, coating, pelletizing, pellet coating, stirring, homogenizing, Vacuumised mixing, filtration, evaporation, containment, material conveying, cleaning and fermentation as well as process integration and process automation service.