- "Best place for one stop solution"

- 91-9898070475

- info@applepackprocess.com

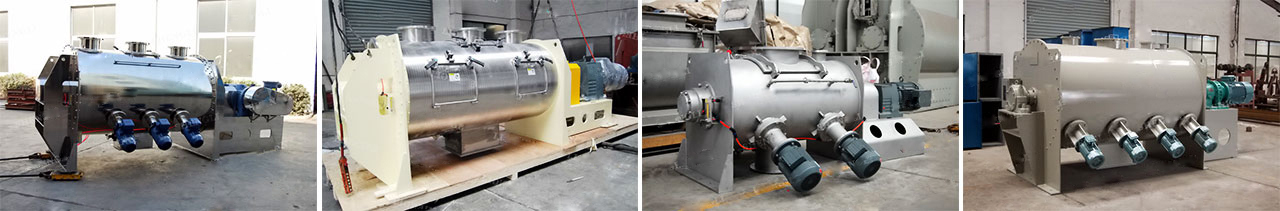

Plough Shear Mixer / Plough Mixer / Plow Mixer / Ploughshare Mixer

Lube oil blending plant, lube oil bender, Lubricant Blending Plant

October 18, 2022

Rapid Mixer Granulator, High Shear Mixer Granulator, High Shear Inline Mixer

October 21, 2022Plough Shear Mixer / Plough Mixer / Plow Mixer / Ploughshare Mixer

Plough Shear Mixer / Plough Mixer / Plow Mixer / Ploughshare MixerPlough mixer machine is widely used to mixing powder, granules with small liquid additives in foods, chemicals, and constructions chemical line.

It is particularly good at handling food additives, fertilizing, sludge, mortars, plastics & building materials. The powerful shearing effect makes it high efficiency with high Quality mixing result.

Technical Details:

- Batch working volume: 100 Liter -20000 Liter

- Batch weight: 300 Kg to -15000 Kegs

- MOC Material: 316L, 304, mild steel

Plough shear mixer is a single shaft mandatory mixing accoutrements . Several pieces of plough shears are installed on the main shaft in disturbance and continuously, which avoid the mixing dead zone in structure.

When operating, material in mixer tank move following the direction of the nonstop whirlpool centrifugal force generated by the continuously blending plough shears, therefore to achieve scattering, dispersing and fast mixing of material.

Special material like fiber or some damp agglomerate material, high speed eggbeater can be installed inside mixer tank to smatter, apportion these accoutrements with combination of plough shear mixing kindler.

The high speed copters are deposited at the barrel side over angle of 45 degrees of the plough shear mixer, the eggbeater heads stretch into the barrel. During mixing, accoutrements are driven to the effective range of the eggbeater, and sheared in high speed by it.

| Type | Mixer Volume(L) | Working Capacity (L) | Type | Mixer Volume (L) | Working Capacity (L) |

| APP130 | 135 | 40-91 | APP- 2000 | 2000 | 600-1400 |

| APP 300 | 310 | 60-210 | APP – 3000 | 3000 | 900-2100 |

| APP 600 | 610 | 180-420 | APP – 4200 | 4200 | 1260-2940 |

| APP 900 | 920 | 270-630 | APP – 6000 | 6000 | 1800-4200 |

| APP1200 | 1250 | 360-840 | APP- 8000 | 8000 | 2400-5600 |

| APP1600 | 1650 | 480-1120 | Further Sizes on demand up to 30000 Lit. | ||

Applications:

- Food Premix & Spice Blending

- Mixing of raw materials

- Mixing of Metal Powders & Bonding material

- Granulation

- Dry mix Mortar

- Homogenization of powder material in Pharmaceutical, Chemical , fine Chemical etc.

Application and Used of Plough Shear Mixer, Plough Mixer, Plow Mixer, Ploughshare Mixer

Plough Mixer, Plow Mixer, Ploughshare Mixer

FOOD industry

Our Plough Shear Mixer, Plough Mixer, Plow Mixer, Ploughshare Mixer can mix food, like milk powder, protein powder, instant noodle, coffee, Eight Ingredient Porridge, MSG, tea, and vitamins; food ingredient, like starch, flour, sugar alcohol, salt,coco powder,spice, dietary fiber. Nuts, meat, cereal etc

food additives and aid, like acidulant, antioxidant, zymin, antiseptic, thickener, food stuff bleacher, raising agent, colorant, edible gelatine Etc.

CHEMICAL INDUSTRY

Plough Shear Mixer, Plough Mixer, Plow Mixer, Ploughshare Mixer for Epoxy resin, pp, Fluorine, silicon, oil comprehensive chemicals and drilling fluid, completion fluid, Coal catalyst, and coal chemical products; magnesium salt, boron compound and borate, chromium salt, fluorine compound, silicon compound, silicate and related inorganic chemical industry; activated carbon, calcium carbide, carbon black, titanium dioxide etc; fluoresces, catalyst, surfactant, water treatment chemicals, flavors and fragrances, copper, manganese, zirconium, nickel powder metallurgy etc; refractory matter, thermal insulation material, carbon material, rot proof coating for metal, powder lubricant, rust preventives, textile dyestuff.

CONSTRUCTION INDUSTRY

Plough Shear Mixer, Plough Mixer, Plow Mixer, Ploughshare Mixer for Mixing construction material, including wall covering material, like natural stone coating, waterproofing coatings, refractory matter, powder paint; dry-mixed mortar, like thermal mortar, anti-crack mortar, and special mortar; additives, like thickener, adhesive, building admixture; sanitary ceramics, like artificial marble, floor title, glaze materials, foamed cement etc, cellulose ether, emulsion powder, PVA, antibiotic agent, methylcellulose, reinforced fibers, water reducer, retarder, deformer, accelerator, thyrotrophic agent, super plasticizer, hardener etc; plaster, artificial sand, natural sand, slag, coal ash, Partite, recycling aggregate.

BATTERY INDUSTRY

Our Plough Shear Mixer, Plough Mixer, Plow Mixer, Ploughshare Mixer serve all kinds of battery material: Lithium battery positive material, like Lithium cobalt oxide, lithium manganese oxide, manganese, nickel and cobalt composite oxides, Lithium vanadium oxide and Lithium iron oxide; Lithium battery negative material, like artificial and natural graphite, MCMB, petroleum coke, carbon fiber, Pyrolytic carbon materials; and some other kinds of kinds of storage battery. The battery that was mixed by our equipment, has been widely used to famous mobile phone, car, camera, and cell-driven vehicles.

Plough Shear Mixer Plough Mixer, Plow Mixer

Product Operation – General

Flexible material selection

Plowshare mixer Material can be carbon steel, manganese steel, ss304, 316L besides, different material can also be used between the part contact with the raw material and the parts don’t contact with the raw material. Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

Plough Mixer – Plough Mixer with Chopper GMP and Non GMP model

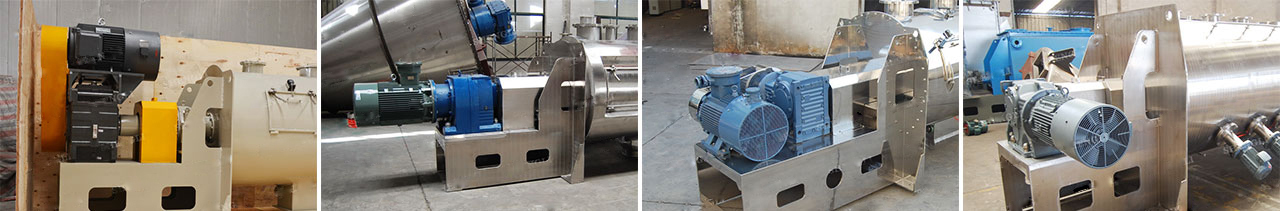

Ploughshare Mixer – Reliable driven unit

The driven unit, power and output speed are varied according to different raw material, starting method, and processing. Options for motor: General Motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor. Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer. Commonly motor gearbox connection: direct connection, pulley connection, hydraulic coupler connection.

Plough Mixer – Gear Box Motor Drive

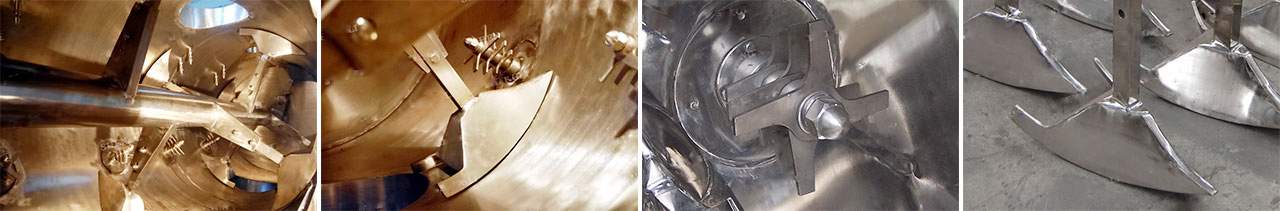

Ploughshare Mixer – High efficiency mixing unit.

The plow heads in the plough shear mixer can be dismountable, which is convenient for replacement. Wear-resistance treatment is done on the plow, making the plow more durable to the severe wear conditions. Different main shaft agitators can be equipped according to the properties of raw materials.

Main shaft agitators: ordinary plough, saw-toothed plough, and shaver-shaped paddle; High speed chopper: multiple-piece cross blade, double-piece lotus blade.

Plough Mixer+ Chopper

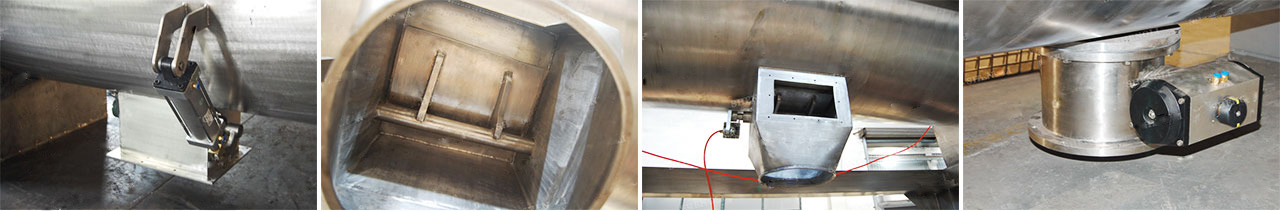

Ploughshare Mixer – Excellent discharging unit

Standard valve for horizontal plough shear mixer is pneumatic planar flap valve. When close the valve, the planar flap matches the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect. The drive types of valves are Manual, pneumatic, and electric. Valves for option: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

Applepack – Discharge Valve

Ploughshare Mixer – Powerful auxiliary components

Mixer is equipped with many auxiliary components, like steam coil jacket, honeycomb pressure jacket, medium circulation jacket, sampling valve, high speed chopper, temperature sensor, weighing system, dust removal system and so on. Different heat medium requires different jacket, it can be used for heating and cooling, while the temperature should be within 250 Celsius degrees. If a small quantity of liquid is required during mixing, spraying or atomizing unit is necessary in order to mix the liquid evenly with the main ingredient. The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles.

Plough Mixer – Jacked, Plow , Window – Chopper + Spraying