Mixers comprise of two high speeds high shear cowlers, and one central anchor agitator with PTFE scraper blades. The top lid with drive arrangement can easily be lifted with an inbuilt, robust hydraulic arrangement.

The salient features of our mixers are-

- GMP design, and construction with factory insulation and SS cladding

- Capacities ranging from 100Kg to 1000Kg.

- Two high speed robust cowler agitators with double mech seals and thermosyphon cooling

- Self adjusting solid PTFE block scrapers ensuring complete scraping, and enhanced heat transfer

- Stainless steel control panel housing variable frequency drives

Automatic Toothpaste Manufacturing Plant, Toothpaste Making Machine

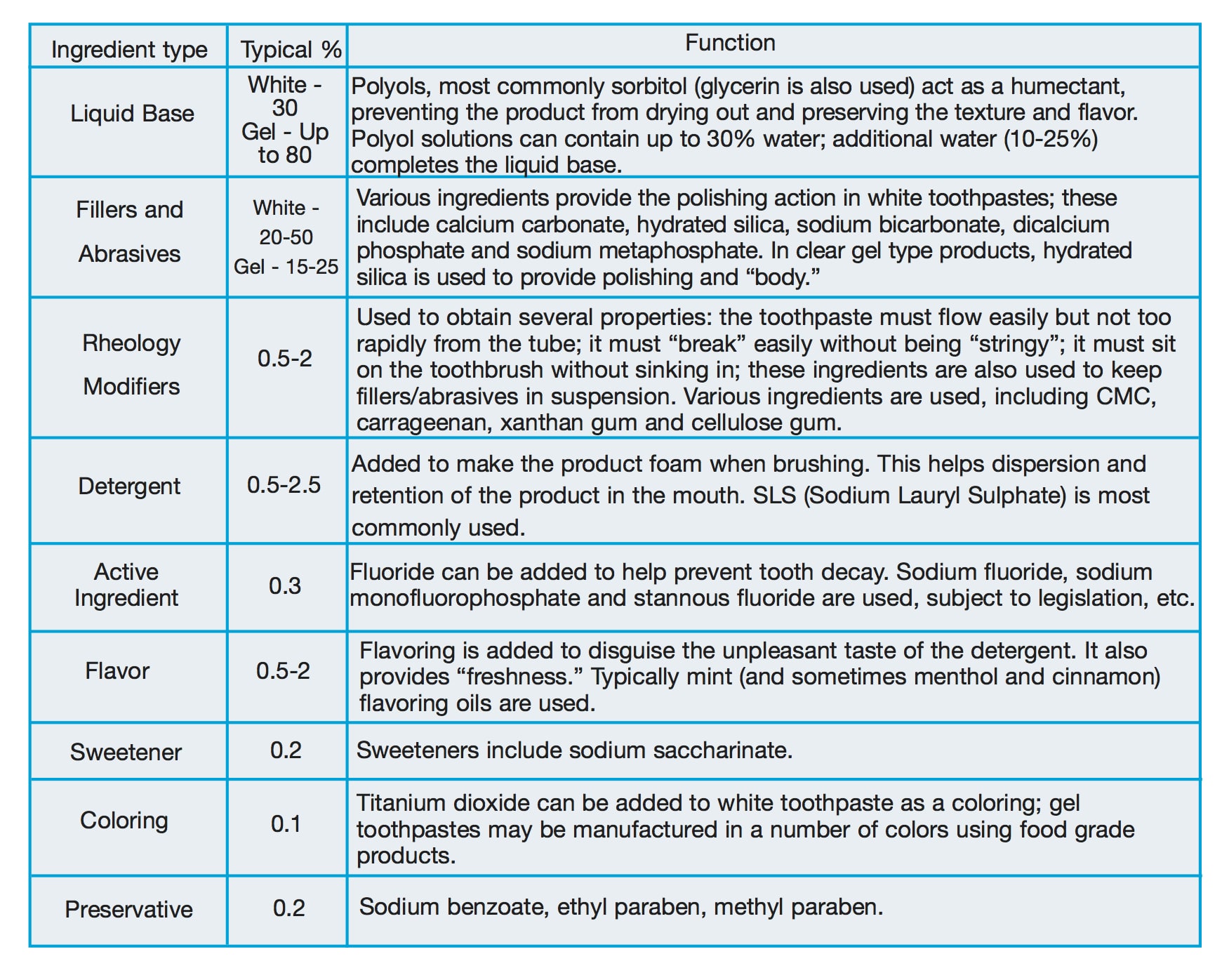

Toothpastes are generally either white abrasive pastes or clear gels. Although the formulations differ, they share many common ingredients; these may vary from country to country according to legislation on use of ingredients, etc.

Toothpaste Manufacturing Plant – Toothpaste Plant

Typical ingredients and their function are shown in the table:

Processing methods vary depending on the product type and ingredients used. A typical process could be described as follows:

- The liquid base is prepared first – water, sorbitol/glycerin and other liquid ingredients.

- Rheology modifiers may be pre-mixed with a non-aqueous liquid ingredient such as glycerin or the flavoring oil, or dry blended with other powdered ingredients to aid dispersion.

- The active ingredient, sweetener and preservative are added and dispersed.

- The abrasive/filler is then added. This may be supplied as a slurry, or premixed with part of the water prior to blending with the liquid base.

- Flavoring and coloring are added.

- The detergent is added last under slow speed agitation to minimize foaming. It is typically in solid form to avoid adding water to the formulation at this stage.

Toothpaste Manufacturing Plant – Toothpaste Plant, Contra mixer ,fryma toothpaste mixer, Toothpaste Mixer and Plant ad mixer process – homogenizing; mixing; dispersing; heating; cooling; deaeration; deagglomeration. Main applications: toothpaste; creams; sealants; lotions and pastes etc….